The FTL management has a strong experience in the hydrocarbon downstream sector, and have been in charge of several international projects.

Experience

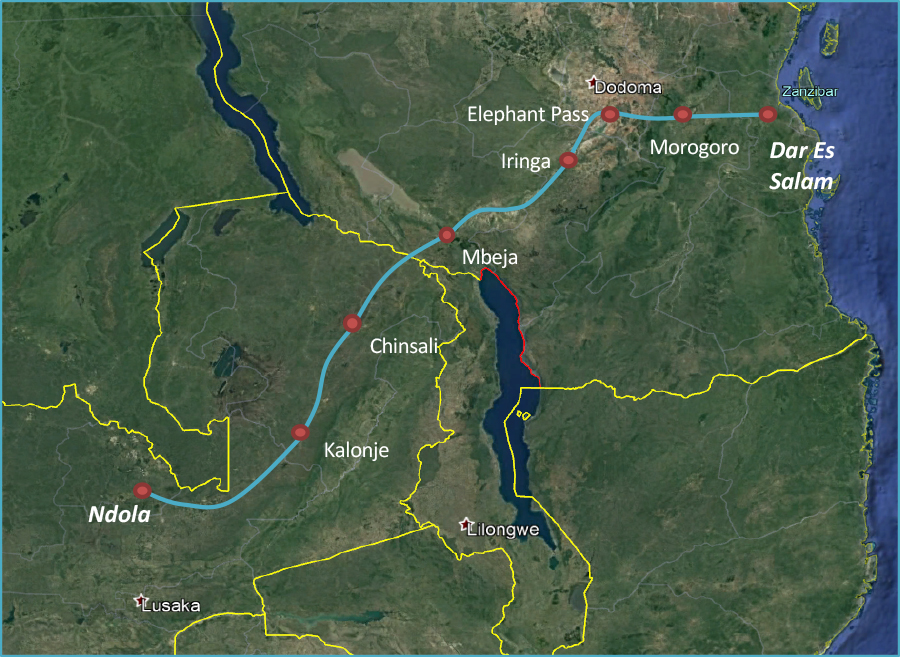

TAZAMA Pipeline

The pipeline carries crude oil from the Dar Es Salaam Refinery/Tank Farm to Ndola in Zambia where the crude oil is stored and thereafter processed.

- Length 1’710 Km

- Size 8”-12” Ø

- No. pumping stations 7

- FlowRate 230 cm/h (1.8 Mlcm/year)

- Storages Dar Es Salam 232’000 cm (6 Tanks)

Ndola 60’000 cm

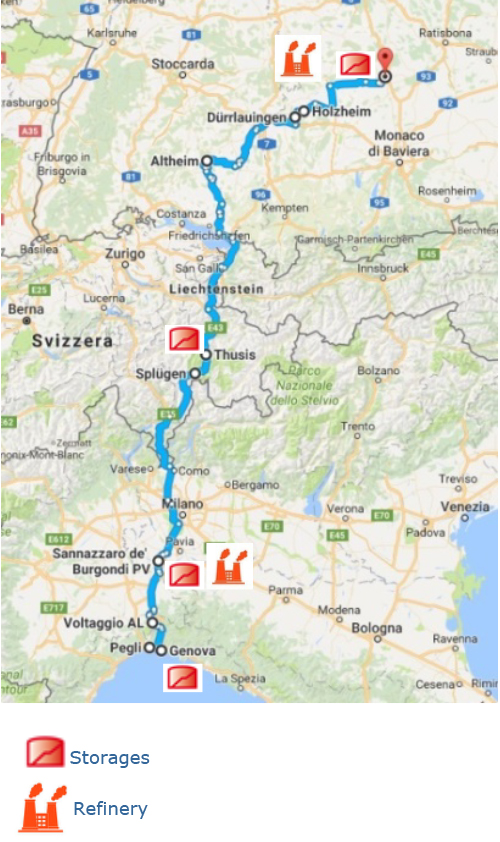

CEL Pipeline

The pipeline carries crude oil from Genova to the refinery in Ingolstadt, north of Nuremberg with the following features.

- Length 1’245 Km

- Size 12’’-32’’ Ø

- No. pumping stations 7

- FlowRate 2’400 cm/h to Sannazzaro – 1’200 cm/h to Ingolstadt

- Storages 3’500-120’000cm Pegli (15 tanks) 2,3Mlcm Sannazzaro (170 tanks) 4’000cm Altheim (10 tanks) 2,5 Mlcm Ingolstadt (100 tanks)

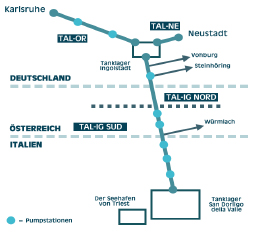

TAL Pipeline

The pipeline carries crude oil from the Trieste Port to Ingolstadt, north of Nuremberg, with the following features:

- Length 753 Km

- Size 26’’-40’’ Ø

- No. pumping stations 10

- FlowRate 7’500 cm/h (45 MlTon/year)

- Storages 2,03 Mlcm San Dorligo (32 tanks)

318’000 cm Lenting (7 tanks)

Algeria-Tunisia-Italy Pipeline

The pipeline known also as TMPC – Trans Mediterranean Pipeline Company carries natural gas from the Algerian fields to the Italian network with the following main features

- Length 2’475 Km

- Size 26’’-42’’ Ø

- No. compression station 8

- FlowRate 3,3 Mlcm/h (26 Mldcm/y)

- Storage 3,5 Mldcm underground

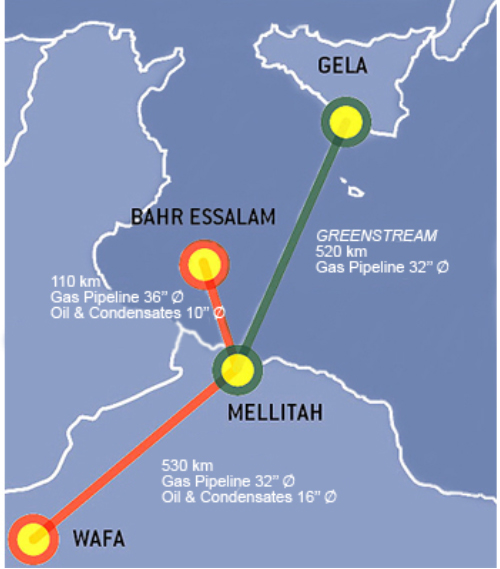

Libya-Italy Pipeline

The pipeline known also as Greenstream carries natural gas from the Libyan fields (mainly Wafa) to the Italian network with the following main features

- Length 520 Km

- Size 32’’-36’’ Ø

- No. compression stations 2

- FlowRate 1,5 Mlcm/h (12 Mldcm/y)

- Storage 2,3 Mldcm

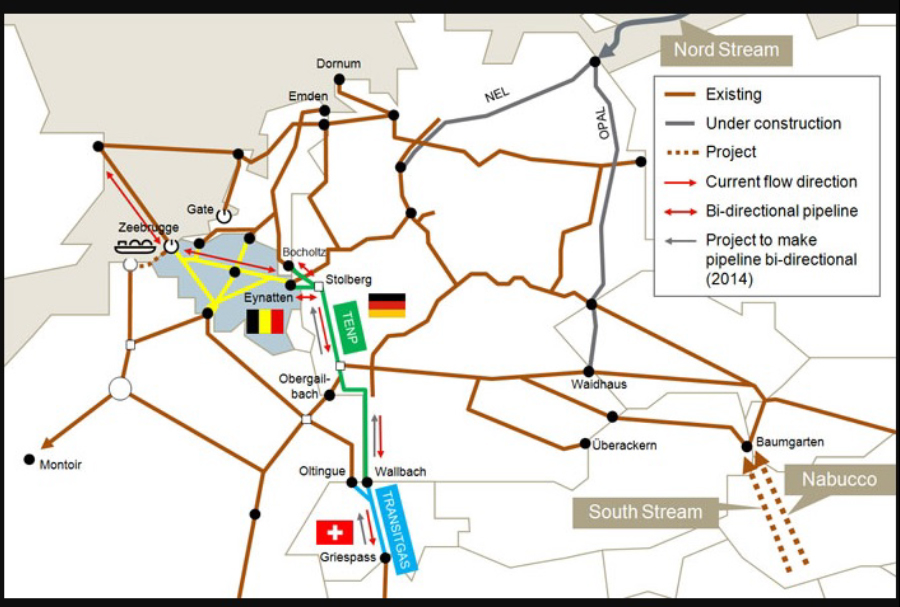

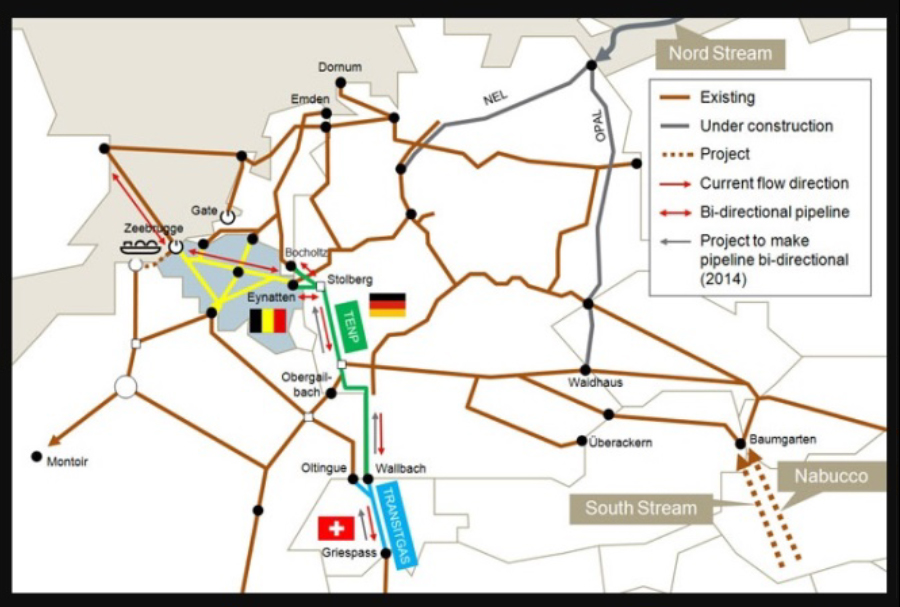

Norway-France-Italy Pipeline

The pipeline carries natural gas from the Norwegian fields in the North See to the Italian network with Entry Point in the North where the Holland-Germany-Switzerland-Italy pipeline is landing. The main features are the following

- Length 1150 Km

- Size 26’’-36’’ Ø

- No. pumping stations 4

- FlowRate 1,5 Mlcm/h (12 Mldcm/y)

- Storages 2,3 Mldcm

Holland-Germany-Swiss-Italy Pipeline

The pipeline carries natural gas from the Dutch fields (Groningen) to the Italian network through Germany (TENP) Pipeline and Switzerland (TRANSITGAS Pipeline) with the following main features

- Length 1’260 Km

- Size 36’’-40’’ Ø

- No. compression stations 5

- FlowRate 1,3 Mlcm/h (10 Mldcm/y)

- Storages 1,5 Mldcm

Russia-Ukraina-Slovakia-Austria-Italy Pipeline

The original pipeline system to receive the natural gas from Russia (Gazprom) has been revamped several times in the years and, today, the system can deliver to Italy approx. 30 Blcm/year. The Russian seller (Gazpromexport) delivers much higher volumes into Slovakia where the pipeline system divides in two arms: one to Germany and the other one to Baumgarten (Austrian-Slovakia border).

The main features of the pipeline are the following

- Length 385 Km

- Size 17’’-40’’ Ø

- No. pumping stations 3

- FlowRate 3,3 Mlcm/h (26 Blcm yearly)

- Storage 3,5 Mldcm

DRC: 700 km Network Of Multiproduct Pipelines

Operations, maintenance, projects and inspection services of the following installations :

- Import multiproduct pipelines, PL46&66) : 2×6”x335km from Matadi to Kinshasa with maximum annual capacity around 1200-1400km3/year;

- 4 dedicated product pipelines in Kinshasa (+/-50km : 3×6”; 1×10”)

- 4 pump-stations and interfaced storage terminals

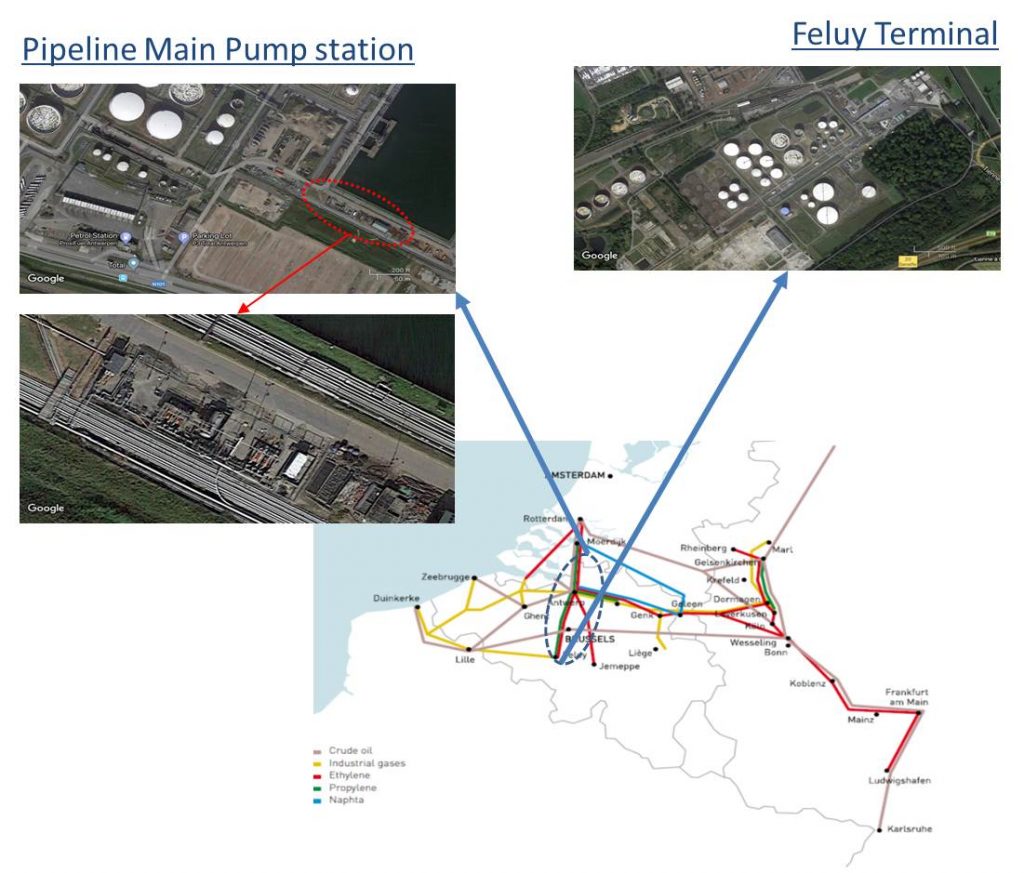

100 km multiproduct pipeline from Antwerp Refinery to Feluy Terminal

Operations, maintenance, projects and inspection services of the following installations:

- 12” multiproduct pipeline (100km) – Intelligent pigging project

- Main pump-station and section valve stations – Rehabilitation project

- New control room in Feluy Terminal with highest standard of safety automated procedures

Integrated Gas Project including onshore LNG regasification, storage terminal and high pressure gas transmission systems

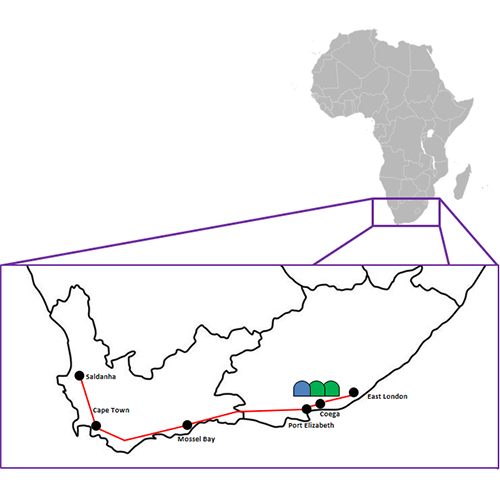

The integrated Project proposed by Tamasa, a joint venture between Medea Dev. SA and CIH (Community Investment Holdings), is to realize a LNG regasification plant and the relevant transmission system that will enable:

- the set-up of an additional and significant alternative energy source in South Africa

- to create competition in the natural gas market and, therefore, creating economic and strategic benefits for the national industry

- to create jobs and secondary industries

- to create a national gas industry of the proper “economy of scale” allowing competitive supplies.

1° Phase

- Liquefied Natural Gas (LNG)

receiving and regasification Terminal at the Ngqura Port

– 1 storage tank of 165,000 liquid cubic meter

– up to 4 Billion cubic meter/year of total regasification capacity - Natural Gas Transmission System

from Ngqura Port to Mossel Bay

– 391 km of pipelines with the diameter ranging from 30” to 36”

2° Phase

- Liquefied Natural Gas (LNG)

– up to 2 more storage tanks of 165,000 liquid cubic meter in addition to the existing one

– up to 8-10 Billion cubic meter/year of total regasification capacity - Natural Gas Transmission System

– 755 additional km of pipeline to connect Cape Town and Saldanha

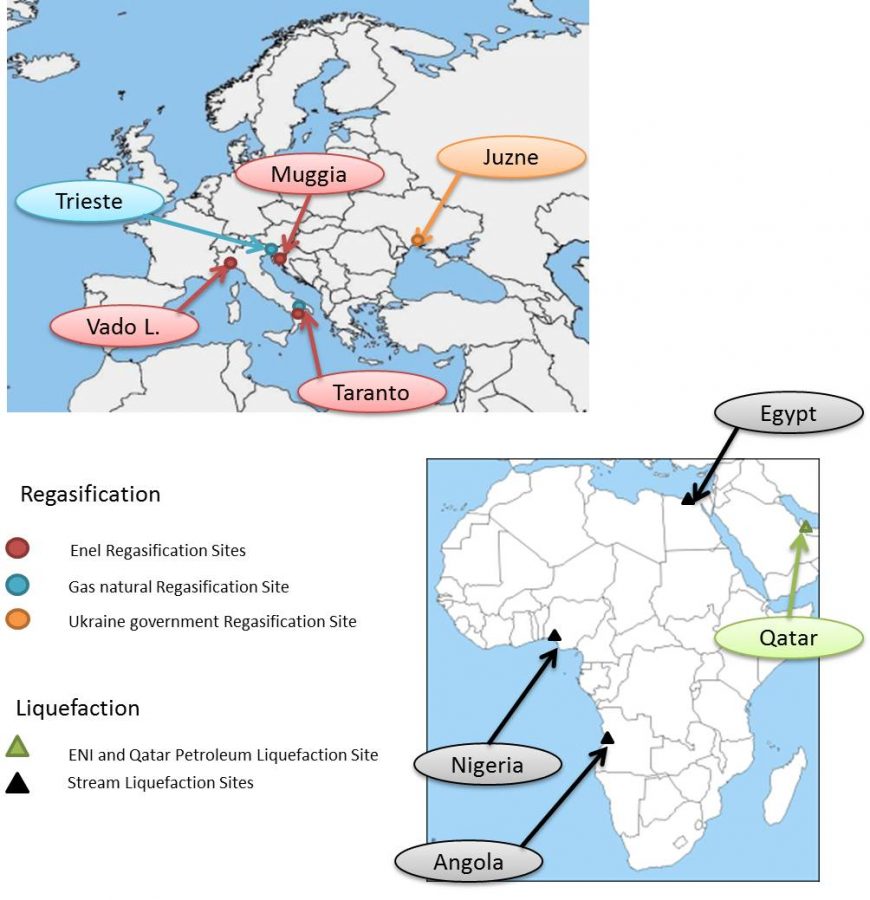

LNG Regasification and Liquefaction Terminals

FTL team provided Engineering, technical studies and support in the LNG sector for the following tasks:

Upstream and supply development

Technical

- LNG liquefaction plant;

- Identification of LNG sources and assessment;

- Off-shore/On-shore gathering and treatment system;

- Maritime transport assessment and optimization.

Commercial

- International Pricing and Benchmarking;

- Basic Agreement;

- SHA (Shareholders Agreement);

- PDA (Project Development Agreement);

- SPA (Supply Purchasing Agreement);

- LNG maritime transport Contracts.

Economic/Financial

- Business Plan;

- Financial assessment;

- Negotiations Support.

LNG Regasification Terminal

Technical

- Technical-economic feasibility studies

- Preliminary Engineering (pre FEED);

- Environmental Impact Study and Safety Report;

- Maritime Transport simulations;

- Institutional and authorization supports;

- Authorization Procedure.

Regional focus on the projects carried out by the team